Manufacturing

Manufacture and assembly of traditional earthenware stoves in the Haut-Rhin

Our artisan workshop makes all the earthenware and ensures the assembly of stoves in the purest of traditions. The inner body of our stoves consists exclusively of clay-mounted refractory bricks. Our stoves thus meet the characteristics of so-called «mass» stoves, diffusing their heat by radiation, with a reduced consumption of wood.

Each stove is the subject of particular attention, as to the choice of the model of earthenware, their colors and decorations, they are made in respect of the request of each customer.

We ensure delivery and assembly throughout the hexagon, for a fee for travel and stays.

Attentive and precise, we offer all refractory stoves mounted entirely by hand (earthenware included). We make mass stoves, efficient and ecologically correct (very little wood consumption).

The steps of making a earthenware stove

Preparation of materials: The materials used to make earthenware stoves are mainly clay, silica and kaolin. These materials are mixed together in precise proportions to create a paste that will be used to make the elements of the stove.

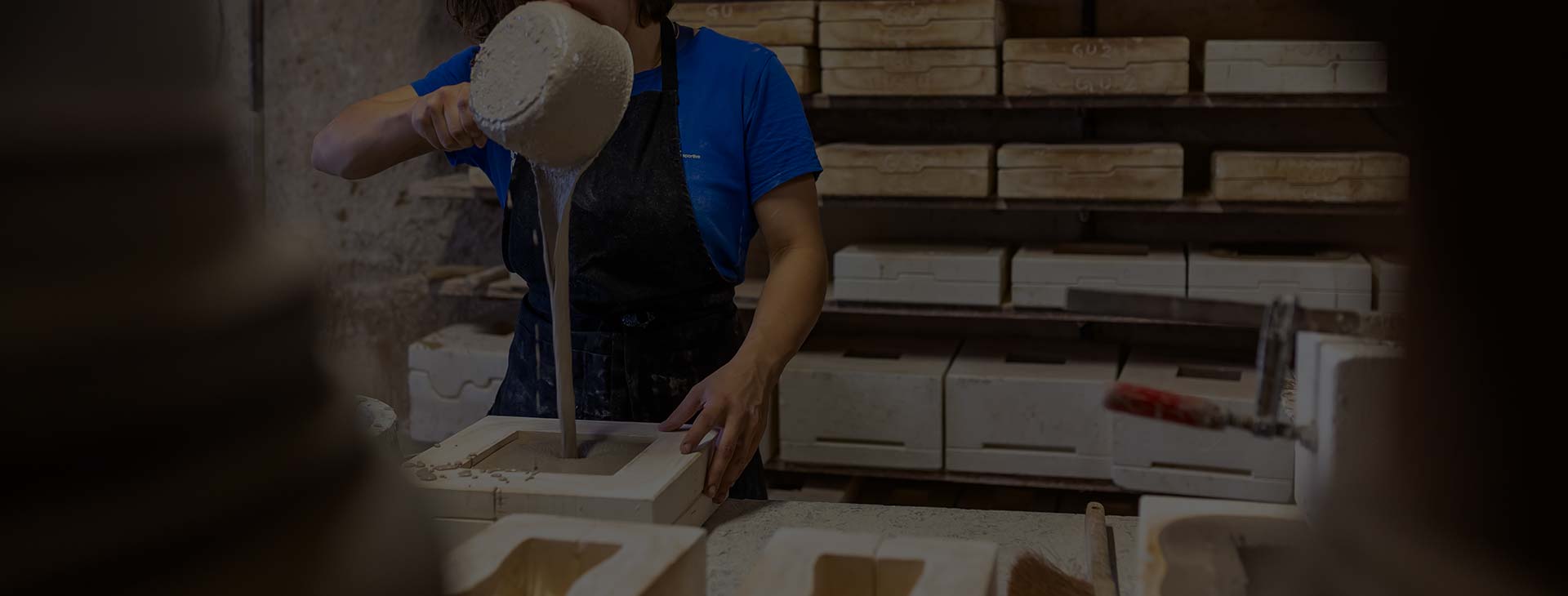

Molding: The dough is then molded into shapes to create the different pieces of the pan, such as the body, feet, handles, etc. The pieces are then left to dry for several days to eliminate excess water.

Cooking: The pieces are then cooked at high temperature in an oven. This hardens the parts and makes them more heat resistant. The temperature and cooking time vary depending on the size and shape of the pieces.

Painting: After cooking, the parts are painted and unmasked according to the manufacturer’s wishes. This gives them a colorful and brilliant look.

Assembly: The different parts of the stove are then assembled to form a single device. The parts are glued together and welded to ensure a good seal.

Inspection and testing: Before shipping, the stove is inspected to ensure it meets quality and safety standards. It is also tested to make sure it is working properly.